Process Hazards Key Safety Principles:¶

Replace the hazardous material or process

Reduce the quantity of hazardous material

Reduce the time the hazardous material is present

Reduce the number of people exposed

Key Tools for Safe Operations:¶

Hazards Analysis (HA) - An incident investigation before the incident (HAZOP, FMEA, FTA, etc.)

Process Safety Information (PSI) - Information about the process and hazards of the materials

Other PSM elements such as Management of Change, Operating Procedures, Training, Pre-Startup Safety Review, Mechanical Integrity, Hot Work Permit, Emergency Planning and Response, Incident Investigation, and Compliance Audits

Project Components¶

Process Background, Scope, and Details

Process Flow Diagram (PFD) or Piping and Instrumentation Diagram (P&ID)

Process Safety Information

Any Incident Investigation Reports or Details

Hazards Analysis

Process Impacts (Ethical, Global, Economic, Enviornmental, and Societal)

Documentation

Process Impacts¶

Ethical - How does the process impact the ethical standards of the company and the industry? Or What ethical decisions may led to a potential incident? How could those decisions be different, from an ethical standpoint?

Global - How does the process impact the global community? Is there a difference in how the process or incident is viewed in different countries?

Economic - How does the process impact the economy?

Environmental - How does the process and potential incidents impact the environment?

Societal - How does the process impact society? Does it change the attitudes of the public towards the company or industry?

Example Analysis: Primary Explosive Material Transfer¶

Process Background and Scope¶

In the defense industry, primary explosives are used in the production of ammunition and other devices. These materials are sensitive to heat, shock, electrostatic discharge (ESD), impact, and friction. The process of transferring these materials from one location to another during processing occurs regularly. One such scenario is the transfer of a small quantity of Compound B from a pass-thru box to a hopper that feeds a press. An operator carries the Compound B in a small jar from the pass-thru box to the hopper. The scope of the analysis is from the time the operator picks up the jar of Compound B to the time the jar is emptied into the hopper.

Process Flow Diagram¶

This animated gif shows the process of moving a small quantity of material in a jar from the pass-thru to the the hopper.

Figure 1:Primary Explosive Material Transfer Process

Incident Description¶

On April 18, 20__, an operator was transferring a small quantity of Compound B from a pass-thru box to a hopper that feeds a press. The operator was wearing a lab coat and gloves. The operator picked up the jar of Compound B from the pass-thru box and was walking towards the hopper when the operator fell. The jar flew towards the hopper and upon impact exploded and caused a fire. The operator was injured and the fire was extinguished by the fire suppression system. The operator was taken to the hospital and treated for burns and lacerations. The operator was released from the hospital the next day.

Figure 2:Primary Explosive Material Transfer Incident

Process Safety Information (PSI)¶

Compound B is a complex of a reactive salt and heavy metals. It is toxic to living organisms and is unstable. It is sensitive to heat, shock, ESD, impact, and friction. It is used in the production of ammunition and other devices. The material is stored in a magazine and during processing, a portion of the storage amount is separated inside a shielded enclosure into a small jar. That jar is then transferred to a hopper that also is shielded. The hopper feeds a press that forms the material into a shape that is used in the production of ammunition.

SDS (Example information for illustrative purposes only)

The SDS for Compound B has the following applicable items:

Physical and Chemical Properties - Compound B is a white powder that is odorless. It is a complex of a reactive salt and heavy metals. It is toxic to living organisms and is unstable. It is sensitive to heat, shock, ESD, impact, and friction.

Stability and Reactivity - Compound B is unstable and is sensitive to heat, shock, ESD, impact, and friction.

Toxicological Information - Compound B is toxic to living organisms.

Handling and Storage - Compound B should be stored in a magazine. During processing, a portion of the storage amount is separated inside a shielded enclosure into a small jar. That jar is then transferred to a hopper that also is shielded.

Exposure Controls and Personal Protection - Operators should wear lab coats and gloves when handling Compound B. Operations should control ESD and avoid impact and friction scenarios.

Small-scale Safety Testing

Safety testing with friction, impact, and ESD devices have shown that the threshold initiation level (a 3.4% chance of ignition) is 30 lbf at 8 feet per second, 10 cm, and 150 mJ, respectively.

Equipment Details

The pass-thru box is a shielded enclosure that has a door on each side. The operator opens the door on one side and places the jar of Compound B inside. The operator then closes the door and opens the door on the other side. The operator then removes the jar of Compound B from the pass-thru box. The hopper is a shielded enclosure that has a door on the top. The operator opens the door and empties the jar of Compound B into the hopper. The operator then closes the door.

Previous Incidents

There have been no previous incidents involving the transfer of Compound B from the pass-thru box to the hopper. However, in a related process, an operator did drop a small quantity of Compound B without incident.

Hazards Analysis¶

HAZOP HAZard and OPerability studies are best suited for processes with flowing materials and multiple inter-related steps. A piping and instrumentation diagram (P&ID) is used to identify the process steps and the materials that flow between them. The P&ID is then used to identify the nodes for which the guide words can be applied.

FTA and FMEA A Fault-Tree Analysis (FTA) and a Failure Modes and Effects Analysis (FMEA) are best suited for processes that have fewer steps but can have a myriad of failure modes. These tools are used to identify the failure modes and the effects of those failures, including safeguards, and recommendations. An FTA and FMEA are better suited to this incident scenario than a HAZOP.

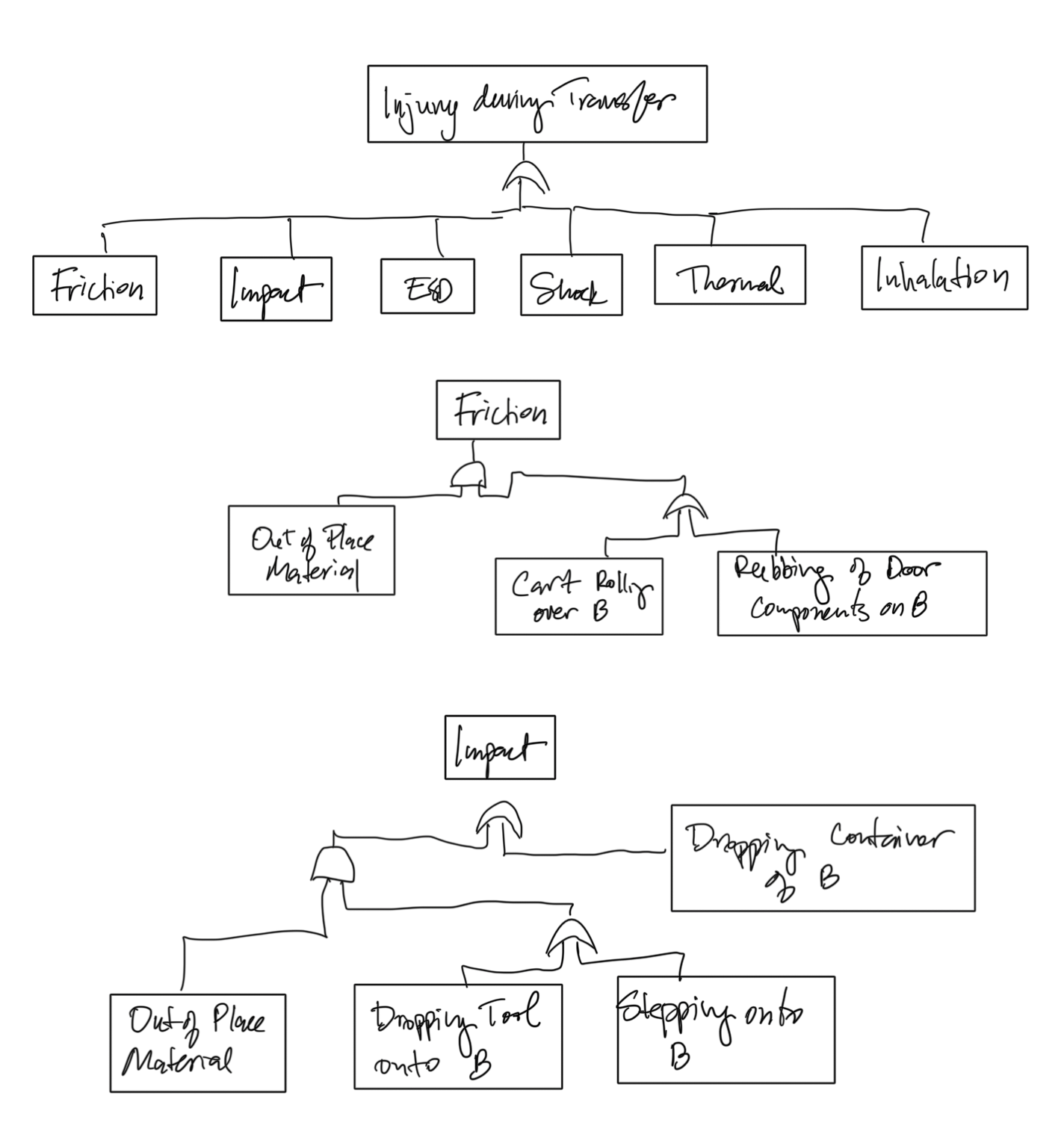

Fault Tree¶

This is a simplified fault tree for the incident scenario. The fault tree shows the top event (Injury during transfer) and the sub events that can initiate Compound B resulting in injury. Just a few of the potential events are given with friction and impact sceanrios.

Figure 2:Example Fault Tree Analysis

FMEA¶

A simplified FMEA of the incident scenario based on the above fault tree is shown below. The FMEA shows the process steps, the failure modes, the effects of those failures, the safeguards, risk rating, and the recommendations.

| Step | Failure Mode | Effect | Safeguards | Risk Rating | Recommendations |

|---|---|---|---|---|---|

| Pass-thru | Operator opens door with out-of-place material | Ignition and potential injury | Pass-thru metal doors are separated on plastic rollers | 🟠 3D | Evaluate preventative maintenance measures for cleaning rollers |

| Pass-thru | Out-of-place material present | Potential ignition and injury | Operator visually inspects pass-thru once a week | 🟠 3D | Evaluate preventative maintenance measures for cleaning pass-thru |

| Operator Transfer | Operator drops jar | Ignition of bulk collection of Compound B | Jar is made from hard plastic potentially reducing impact impulse | 🔴 2C | Use a cart to transfer the jar from the pass-thru to the hopper with the cart under the pass-thru or hopper when the operator lowers or lifts the jar |

| Pass-thru | ESD discharge to material | Ignition of material with injury | 🟠 3D | Operator should wear an ESD wrist strap at that station or have conductive shoes. Consider completing an ESD evaluation to quantify ESD hazards | |

| Operator Transfer | A tool is dropped on the contaminated floor | Ignition of material with injury | The floor is cleaned once a week | 🟡 4D | |

| More FTA Failure Modes | This list is insufficient. All of the FTA items should be adequately addressed |

Process Impacts¶

Ethical - The company has a responsibility to protect its employees from harm. The company should have a robust process safety management system in place to prevent incidents like this from occurring. The company should also have a robust incident investigation process to determine the root cause of the incident and to prevent similar incidents from occurring in the future. Any quantity of explosives material requires compliance with OSHA’s Process Safety Management (PSM) requirements.

Global - The incident could have global implications if the company is a global supplier of ammunition or other devices. The company could lose business if the incident is not handled properly. The company could also face legal action. Specifically, components used to manufacture Compound B is sourced from a country with less than ideal working conditions. The company could consider communicating and aiding the manufacturing country in improving working conditions.

Economic - This incident is not likely to prevent the company from completing the orders it has. However, the company could lose business if the incident is not handled properly. The company could also face legal action. The company could also face fines from OSHA for not having a robust process safety management system in place (if applicable).

Environmental - The incident could have environmental implications if the fire suppression system used to extinguish the fire allowed significant runoff of the Compound B into the environment. The company should have a robust environmental management system in place to capture and treat any flow streams including accident scenarios.

Societal - The incident could have societal implications if the company is a major employer in the area. The company could lose business if the incident is not handled properly, or this incident shows a lack of care for the employees if there is a pattern of incidents.

Documentation¶

Presentation¶

A five minute presentation with up to 30 slides is prepared and delivered with the team members. Since time is so limited, focus on the most important points to convey of the process, previous incidents, specific hazards, specific outcomes, and specific recommendations. You want to convey what should be learned from the process and or incidents with specific details that enforce safety principles.

Memorandum¶

A memorandum is prepared and delivered that has all of the details as exemplified above but to a fuller extent. Specific requirements including a rubic is given in Learning Suite. An example memorandum might include the following sections:

Process Background and Scope - A detailed description of the process and the scope of the analysis.

Process Flow Diagram - A process flow diagram or piping and instrumentation diagram.

Incident Description - A detailed description of any incidents.

Process Safety Information - A detailed description of the process safety information from multiple sources.

Hazards Analysis - A subsection of the hazards analysis (with the full HA after the report as an addendum or appendix).

Process Impacts - A description of the process impacts to global, economic, environmental, and societal aspects.

Recommendations - A highlight of the critical recommendations from the analysis.

Conclusion - A brief summary of the important points.

Example Scenario: Canning Green Beans¶

When I was a child, my family had about 1/3 -1/2 of an acre of land that we cultivated growing vegetables and raspberries. We also had apple, pear, and plum fruit trees. My mother canned lots of vegetables. My father sold real estate in the 1980s, but with interest rates at 13% or more, sometimes he didn’t sell any houses. Thus we ate a lot of canned vegetables, mostly string green beans, that my mom had previously canned. I watched as my mom would use the pressure cooker to seal the glass cans of beans and I wondered if that thing would ever explode.

Your task is to complete a fault tree analysis (FTA) together with a hazards analysis (HA) table to help my mom use her old pressure cooker safely and to help evaluate the risk of canning and consuming the green beans. The stove we had was yellow and it had 4 electric elements that would get red hot if the stove was on high. And yes, we of course had tin foil beneath those elements so we could clean the stove easier.

Below is the procedure for canning. Use this procedure to help you complete the FTA and the HA table (also known as a JHA table). The hazardous top-level event is moderate to severe injury during canning and later consuming the beans.

Procedure¶

Get some fresh string beans from the garden or the store..

Wash and soak the green beans in water for 3 min.

Cut the green beans with a knife into approximately 1-1/2 inch lengths. Also remove the ends and discard.

Sterilize the glass canning jars (quart size) by placing them in boiling water for a few minutes.

After sterilizing the jars, fill them to the top with the cut green beans.

Place the pressure cooker on the stove and add 2 quarts of water.

:width: 701px :alt: Pressure Cooker :align: left :label: Pressure Cooker AI Generated image of a pressure cooker on a stove with electric elements showing the locking lid and the pressure gauge on the top as well as the pressure relief valve.

Sterilize the canning lids (must be new lids) by placing them in boiling water for a few minutes. Take them out and allow them to dry.

Add ½ teaspoon of canning salt (containing iodine) to each of the jars containing the green beans.

Fill each jar with boiling water. Fill to the neck of the jar. Don’t fill all the way to the top.

Wipe the top of each jar with a paper towel to ensure a good seal with the lids.

Place a lid on each jar and screw on the screw lids tightly by hand.

Figure 5:AI Generated image of canned green beans.

Place the jars in the pressure cooker and make sure none of the jars are touching.

Place the lid on the pressure cooker and lock into place.

Turn on the stove and heat until steam exits the port on top of the pressure cooker which should take 5-10 minutes.

After 10 minutes of steam exiting the port, place the canning weight on the port to prevent the steam from exiting.

Keep the heat on until the gauge reads 10 pounds or 10 psi.

Once it reaches 10 pounds/psi, adjust the heat so it stays at 10 pounds. DO NOT LET THE PRESSURE GET NEAR THE BLACK LINE OF DOOM (pressures above 20 psi).

Figure 6:AI Generated image of the pressure gauge with danger indicator.

Set the timer for 25 minutes and start it making sure the pressure stays around 10 pounds. Monitor the pressure regularly.

When the timer goes off, turn off the stove, and allow the pressure cooker pressure to slowly return to zero.

Once the pressure gauge reaches zero, remove the canner weight and open the lid away from your face.

Remove the jars with a jar lifter so as to not burn your hands.

Allow the jars to cool. As they cool, you should hear a popping noise indicating the jars have sealed.

After they have all cooled, check that the lids are sealed by pressing on the top. If the middle of the lid moves up and down with pressure, the can didn’t seal properly.

Store the properly sealed canned grean beans in the food storage room.

Last and not least, remove a previous canned beans quart and open it, warm some of the beans, and enjoy some butter and vinegar with your green beans.

Figure 7:AI Generated image of the canned green beans ready to eat.