Process safety management also covers important topics besides Process Safety Information and Process Hazard Analysis.

RAGAGEP¶

Following significant industrial accidents, government regulations were put in place to create a safer work environment. OSHA or the Occupational Safety and Health Administration was established in the early 70’s. They and others collected and set Recognized and Generally Accepted Good Engineering Practices (RAGAEP). Some of the substantial practices have been codified into law. These practices are the minimum standards that must be followed to ensure a safe work environment. Some of which are given below:

Regulations:

OSHA 29 CFR 1910.119 Process Safety Management (PSM)

EPA 40 CFR 68 Risk Management Programs (RMP)

DHS 6 CFR 27 Chemical Facility Anti-Terrorism Standards (CFATS)

PHMSA/ DOT Shipment of Hazardous Chemicals 49 CFR Parts 100-185

Codes

NFPA 70: National Electrical Code

ASME Boiler and Pressure Vessel Code

Standards

NFPA 45, 68, 69

Many others

OSHA 29 CFR PSM Elements¶

Required for those meeting the Threshold Quantities

Employee Participation

Process Safety Information

Process Hazards Analysis

Operating Procedures

Training

Contractors

Pre-Startup Safety Review

Mechanical Integrity

Hot Work Permits

Management of Change

Incident Investigation

Emergency Planning and Response

Audits

Trade Secrets

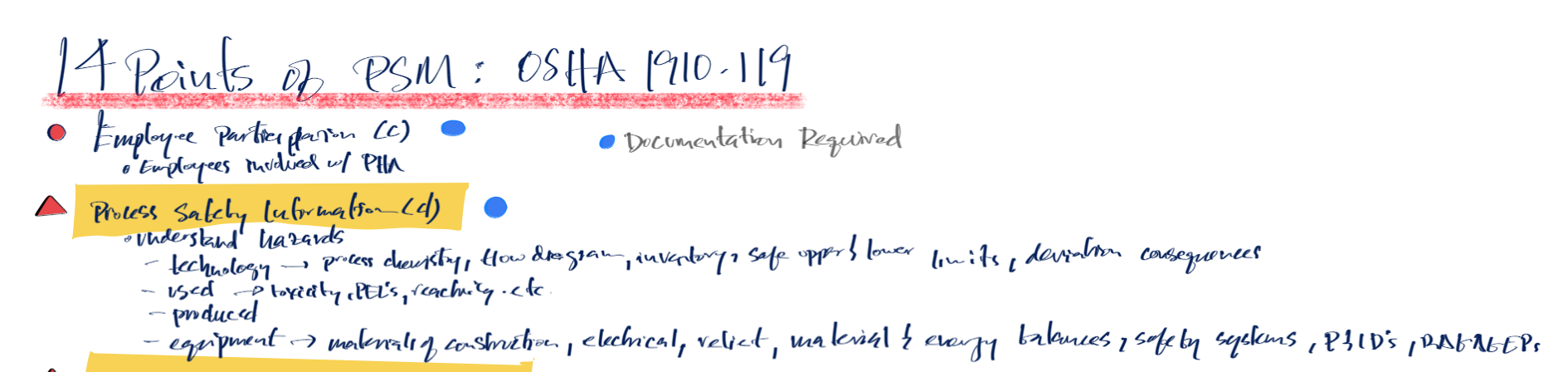

14 Points of PSM: OSHA 1910.119¶

Employee Participation

Employees participate with process hazards analysis (PHAs) for example

Process Safety Information

Understanding the hazards of the process

process chemistry

phase diagram

inventory or processing amounts

safe upper and lower limits for temperature, pressure, etc.

consequences of deviation, etc.

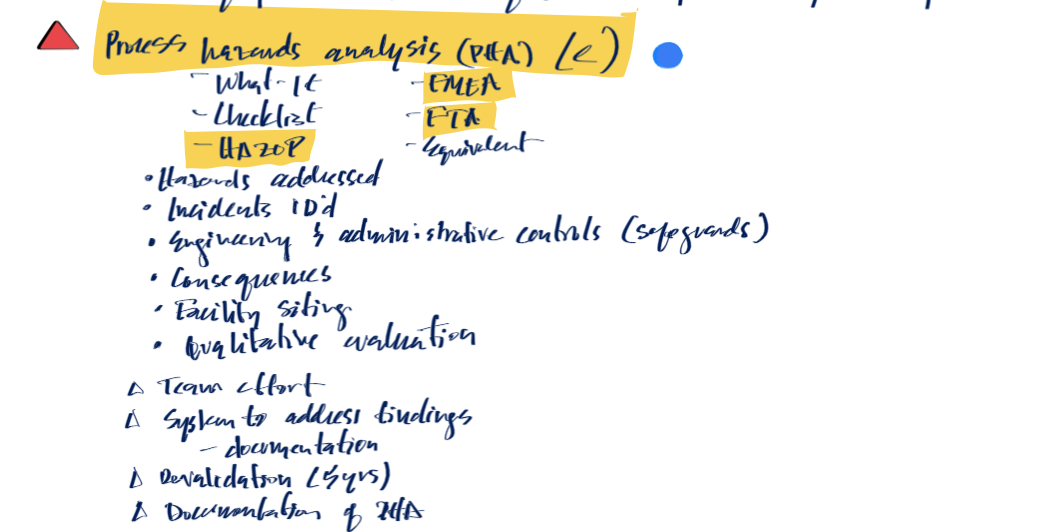

Process Hazards Analysis

FMEA Failure Modes and Effects Analysis

HAZOP Hazards and Operability Study

FTA Fault Tree Analysis

Others: LOPA, What-If, Checklist, etc.

Hazards addressed

Previous incidents and near misses evaluated and included

Engineering and administrative controls (safeguards)

Consequences of failure

Facility siting (location of the facility relative to other facilities and the public)

Qualitative and quantitative evaluations

Team effort

System to address findings and recommendations

Revalidation (every 5 years)

Documentation

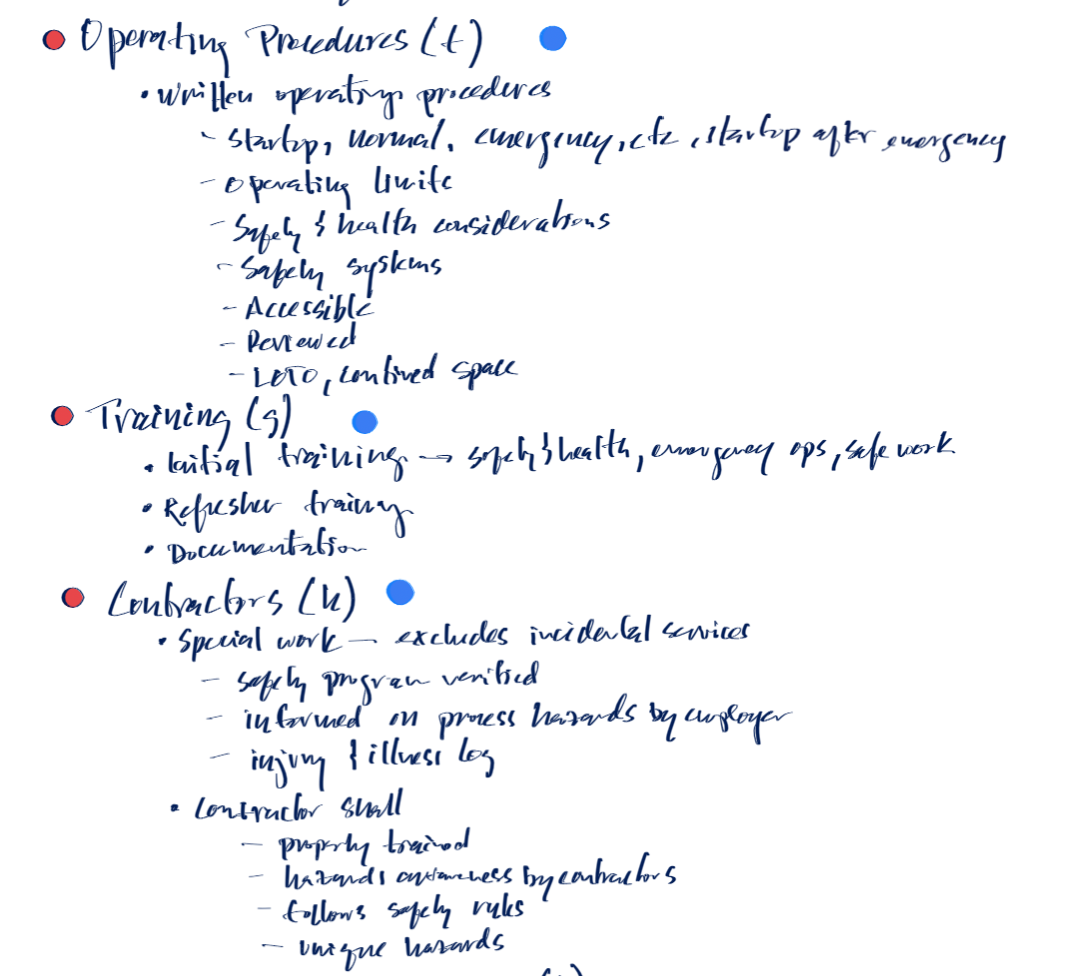

Operating Procedures

startup, shutdown, normal operations, emergency operations, etc.

operating limits

safety and health considerations

safety systems

Accessible and reviewed regularly

Lock and Tag Out procedures

Confined Space Entry procedures

Training

Initial and refresher training

Documentation

Contractors

Prequalification (safety record, training, etc.)

Informed on PHA and operating procedures by the owner

Injury and illness records

Documentation

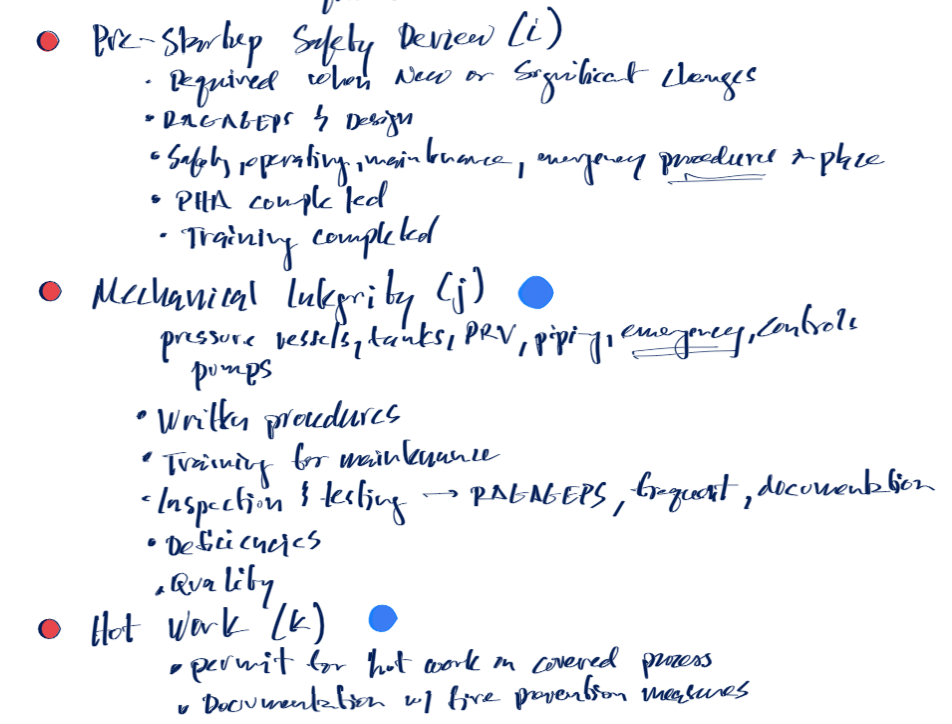

Pre-Startup Safety Review

Required with new processes or significant modification

RAGAGEP (Recognized and Generally Accepted Good Engineering Practices)

Procedures required to be in place (operating, maintenance, emergency, etc)

PHA completed

Training completed

Documentation

Mechanical Integrity

covers pressure vessels, tanks, prvs, piping, emergency systems, controls, pumps, etc.

written procedures required

training for maintenance personnel

Regular inspection with testing

Documentation

Hot Work Permits

Required for welding, cutting, brazing, etc. on covered processes

Fire prevention and protection measures

Inspection of area

Fire watch

Documentation

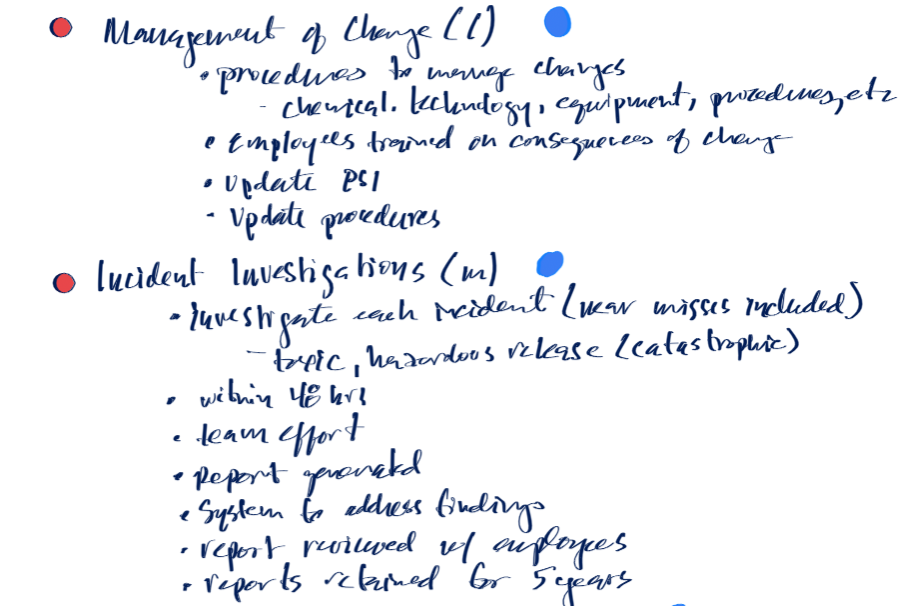

Management of Change

Required for changes in process chemicals, technology, equipment, procedures, etc.

Procedures to manage changes and their consequences

Training required on consequences of changes

Documentation

Incident Investigation

Required for incidents that resulted in, or could have resulted in, a catastrophic release

Team effort started within 48 hours

Report generated

System required to address findings

Report reviewed with employees

Report retained for 5 years

Emergency Planning and Response

Emergency action plan documented and implemented including evacuation, alarms, training, drills, etc.

Compliance Audits

Required every 3 years

Team effort

Report generated

System required to address findings

2 most recent reports retained

Trade Secrets

PSI (Process Safety Information) must be available to employees and contractors

Confidential information can be protected

Employees have access to PSI, the PHA, and other PSM documentation

Example Cases¶

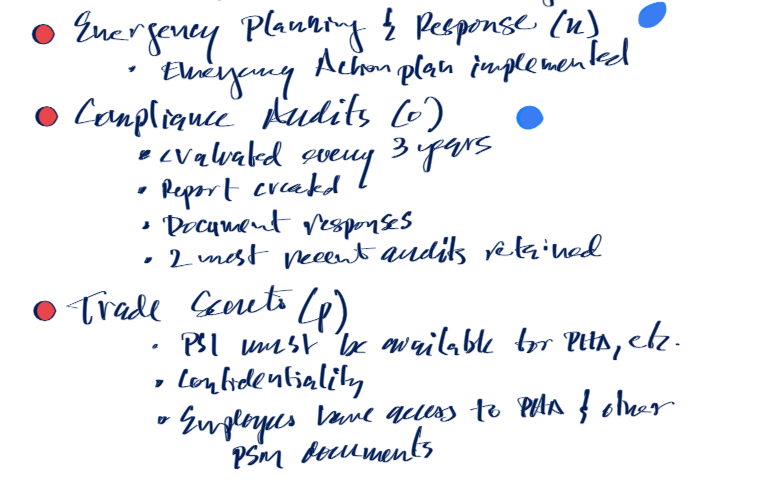

Pressure drop¶

Pressure drop in a hydrogenation reactor from clogged support plate after change in charcoal blend.

Figure 7:Image of the process where a hydrogenation reactor from a clogged support plate resulted after change in the charcoal blend.

Process change¶

Nitration occurs with OH groups replaced by NO2 groups. A nitration reaction was carried out at low temperature and then heated to 90C for 30min and then cooled. Instead of active cooling, the reactor was left to cool down on its own and it exploded throwing pieces 75m away (see reference 7 in Section 2.6 in What Went Wrong, 5th Edition). (Autoignition can be at lower temperature with longer exposure times.)

Gasoline flammability¶

A man who wanted some gasoline for cleaning decided to siphon it out of the tank of a company vehicle. He inserted a length of rubber tubing into the gasoline tank. Then, to fill the tubing and start the siphon, he held the hose against the suction nozzle of an industrial vacuum cleaner. The gasoline caught fire and two vehicles were destroyed and eleven damaged. (Quoted from What Went Wrong, 5th Edition, Section 3.3.3(a))

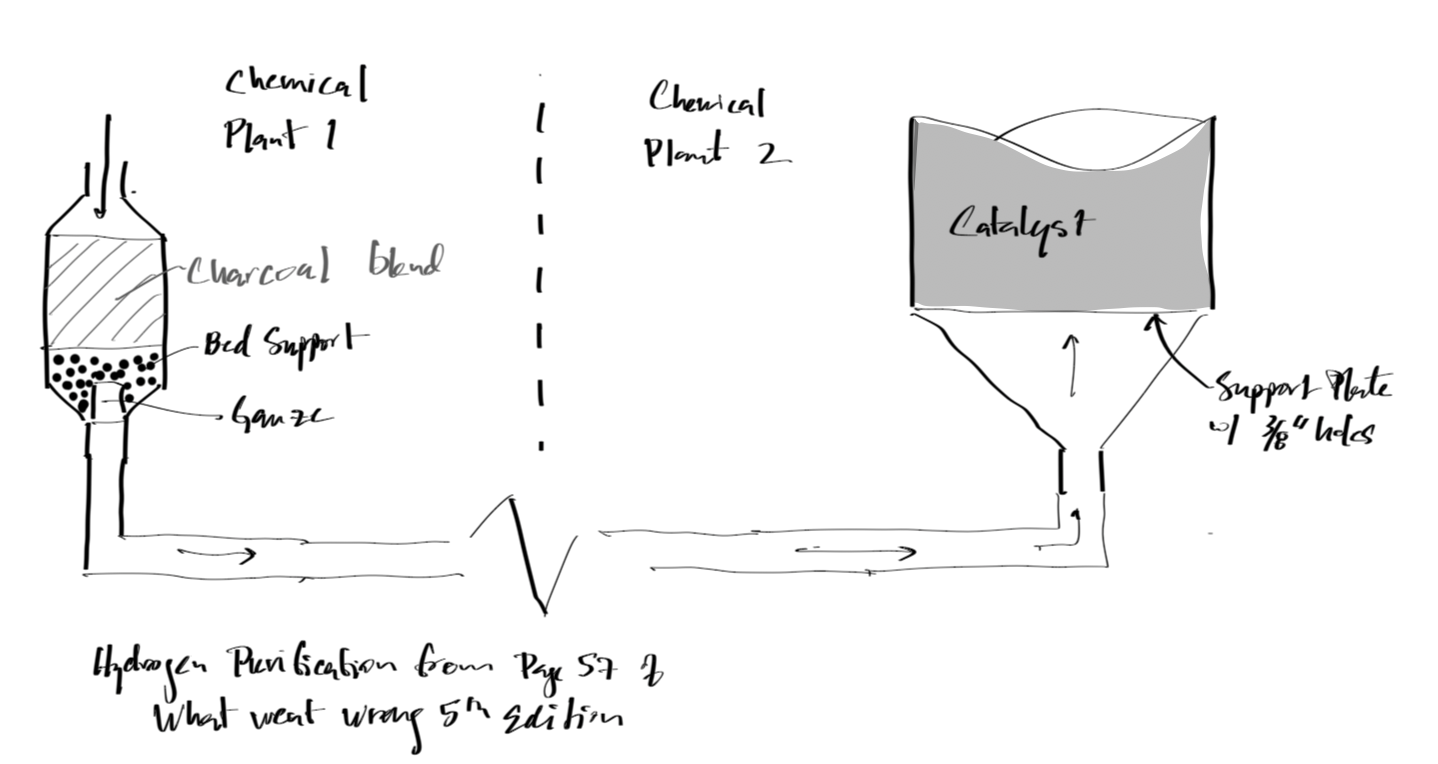

Ethylene Oxide¶

Figure 8:Process flow drawing of an ethylene oxide reactor system.

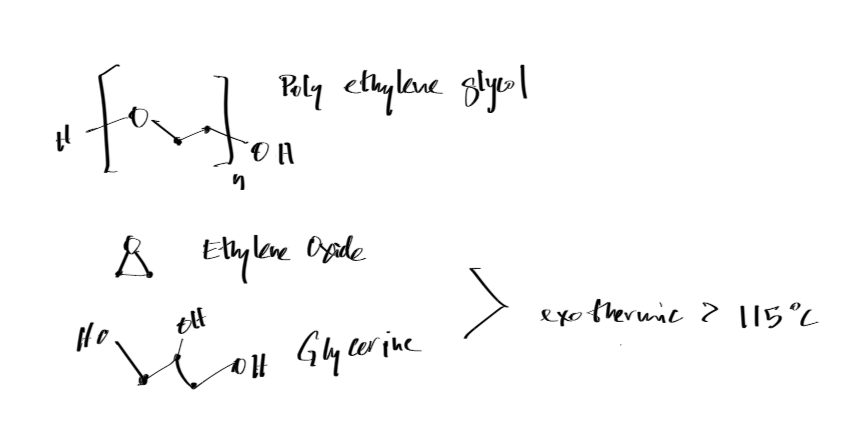

Figure 9:Image of polyethylene glycol, ethylene oxide and glycerine molecules.

The above system with the ethylene oxide pump was setup such that the Pump1 could only operate (engineering controls) when:

the circulation pump (pump2) was running

the temperature was above 115C, as otherwise the ethylene oxide would not react

the temperature was below 125C, otherwise the reaction was too fast

Accident scenario:

The operator thought he had the valve at the bottom of the reactor open but didn’t and running the pump with a dead suction led to the temperature rising, satisfying the conditions for the ethylene oxide to be introduced (pump was running and temperature was between 115 and 125C). He saw the pressure rise (no reaction occurring as ethylene oxide is a gas) so he allowed more heat to the heat exchanger. He then realized that the valve was closed and opened it. An explosion resulted as the reaction occurred very quickly and released a lot of heat.

This scenario taken from What Went Wrong, 5th Edition, Section 3.2.8.

Hot Work¶

Many accidents have occurred from maintenance or other activities with welding, cutting, etc that have ignited flammable materials.

- Guymon, C. (2025). Foundations of Spiritual and Physical Safety: with Chemical Processes.